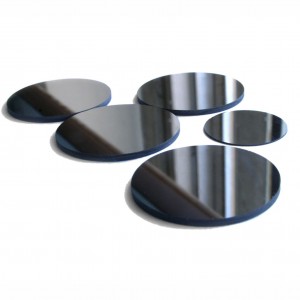

Polycrystalline Cubic Boron Nitride (PCBN) rau Machining Applications

PCBN composites yog tsim los ntawm sintering micron CBN hmoov nrog ntau yam ceramic, thiaj li los tsim cov khoom siv tawv heev thiab thermally ruaj khov Cov khoom siv PCBN Feem ntau yog sib koom ua ke rau cov cemented carbide substrate.CBN yog cov khoom siv nyuaj tshaj plaws thib ob paub tom qab hluavtaws pob zeb diamond, tab sis muaj cov khoom siv thermal thiab tshuaj lom neeg.Nws yog tsuas yog siv nyob rau hauv kev txiav thiab ua cov hardness siab los yog nyuaj rau cov ntaub ntawv xws li hardened steel, grey thiab siab zog cam khwb cia hlau, siab ceev steel, cam khwb cia hlau quench alloy, sintering hlau cov ntaub ntawv, thiab lwm yam.

| Code # | Txoj kab uas hla (mm) | Pob zeb diamond txheej (mm) | Qhov siab (mm) | Abrasive ratio | Feature | Daim ntawv thov |

| TIAB SA 1303 | 13.5 Nws | 0.8-1.0 | 3.2 | > 10000 |

CBN txheej thiab Wc-co substrate Siab CBN cov ntsiab lus 2. Siab hnav tsis kam 3. Zoo rupture lub zog 4.Zoo tshuaj stability | 1. Precise dimension2.Grey cam khwb cia hlau 3.Powered Hlau 4.Kub tiv taus 5. Quenching alloy 6. Cov cuab yeej steel & tuag steel |

| HCF1304 | 13.5 Nws | 0.8-1.0 | 4.5 | |||

| TIAB SA 3201 | 32.0 Nws | 0.8-1.0 | 1.6 | |||

| TIAB SA 3202 | 32.0 Nws | 0.8-1.0 | 2.4 | |||

| TIAB SA 3203 | 32.0 Nws | 0.8-1.0 | 3.2 | |||

| TIAB SA 1303 | 13.5 Nws | 0.8-1.0 | 3.2 | > 3000-4000 |

CBN txheej thiab Wc-co substrate 2. Cov ntsiab lus CBN tsawg tsawg 3. High hnav piv 4. Zoo tiv thaiv rupture lub zog |

metallurgy qhov chaw |

| TIAB SA 1304 | 13.5 Nws | 0.8-1.0 | 4.0 | |||

| TIAB SA 3201 | 32.0 Nws | 0.8-1.0 | 1.6 | |||

| TIAB SA 3202 | 32.0 Nws | 0.8-1.0 | 2.4 | |||

| TIAB SA 3203 | 32.0 Nws | 0.6-0.8 hli | 3.2 | |||

| wb 0903 | 9.55 ib | 3.18 | 3.18 | > 5000 |

|

|

| HB1204 | 12.7 ib | 4.76 ib | 4.76 ib | |||

| HB1608 | 15.85 Nws | 8.0 ib | 8.0 ib | |||

| HB 2008 | 20.0 Nws | 8.0 ib | 8.0 ib |