SND-M10 Synthetic Micron Pob Zeb Diamond Hmoov Polishing Abrasive Rau Lub Hom Phiaj

SND-M10 Synthetic Micron Pob Zeb Diamond Hmoov Polishing Abrasive Rau Lub Hom Phiaj

1. Micron Pob Zeb Diamond Hmoov Taw Qhia

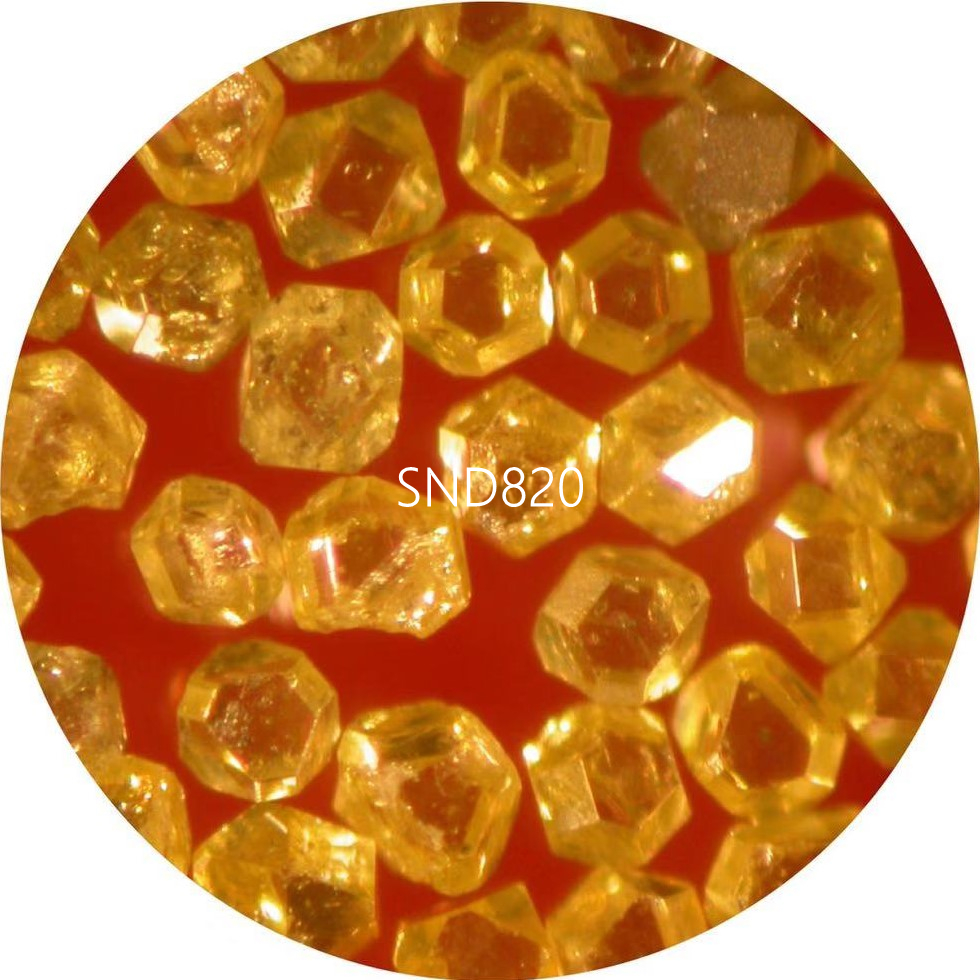

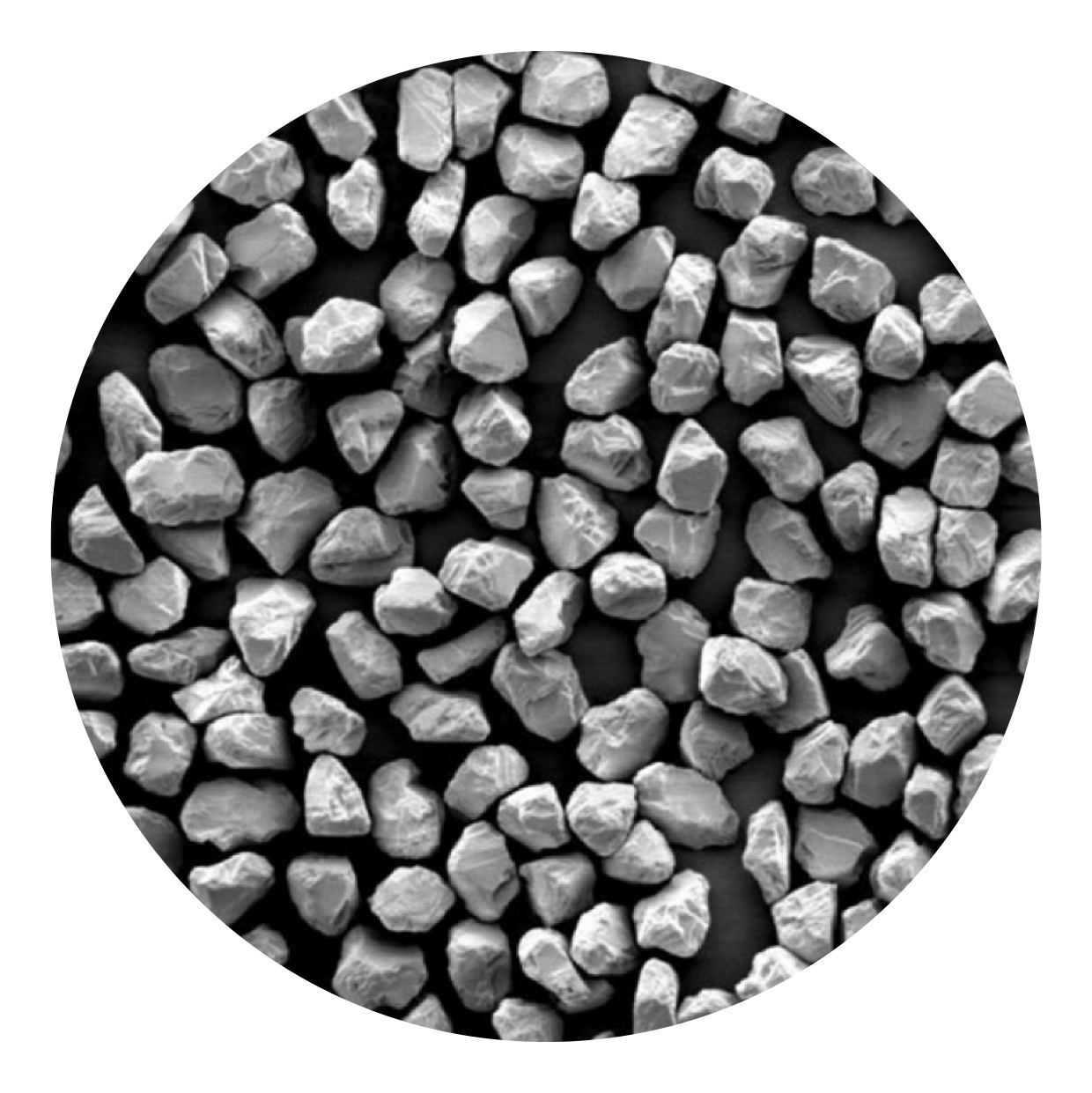

SND-M10 yog lub hom phiaj dav dav micron pob zeb diamond hmoov nrog Irregular siv lead ua duab nrogkuj concentratedparticle loj tis,tsawg impurity cov ntsiab lus.Siabefficiency.Yuav siv tau rau hauvresin,

vitrified, hlau daim ntawv cog lusthiab cov khoom siv electroplated.

2. Specification ntawm Micron Pob Zeb Diamond Hmoov

|  |  |

| SND-M05 0-0.125 ~ 40-60 | SND-M10 0-0.125 ~ 40-60 | SND-M15 0-0.125 ~ 40-60 |

| Irregular crystal puab, impurity cov ntsiab lus thiab particle qhov loj me, tuaj yeem siv tau nyob rau hauv resin thiab vitrified daim ntawv cog lus. Haum rau kev ua haujlwm siab sib tsoo thiab polishing kev siv, xws li pob zeb, vuas, Jade & lub pov haum, thiab lwm yam. | Irregular crystal puab nrog kuj concentrated particle loj tis, tsawg impurity cov ntsiab lus.Siab efficiency.Yuav siv tau rau hauv resin, vitrified, hlau daim ntawv cog lus thiab cov khoom siv electroplated. | Thaiv nplej, kuj concentrated particle loj kev faib tawm, me me impurities, haum hydrophilic kev ua tau zoo.Haum rau high yuav tsum tau lapping, polishing, tuaj yeem siv rau PCD zoo pob zeb diamond muab tshuaj txhuam thiab slurry thiab lwm yam zoo pob zeb diamond khoom. |

3. Micron Pob Zeb Diamond Muaj Grit Loj

| International Standard | Tuam Tshoj Standard | Mesh Loj | Daim ntawv thov |

| 0-0.1 hli | W 0.1 | 100000 | Super Daim iav Polishing |

| 0.0.25 Nws | wb 0.25 | 60000 | Super Daim iav Polishing |

| 0-0.5 hli | wb 0.5 | 30000 | Daim iav Polishing |

| 0-1 | W1 | 15000 | Daim iav Polishing |

| 0-2 | W1.5- | 13 000 | Zoo Polishing |

| 1-2 | W 1.5 | 12000 | Zoo Polishing |

| 1-3 | W 2.5 | 10000 | Zoo Polishing |

| 2-4 | W 3.5 | 6500 ib | Zoo Polishing |

| 2-5 | W4 | 5000 | Zoo Polishing |

| 3-6 | W5 | 4000 | Zoo Polishing |

| 4-6 | W6 | 3500 | Zoo Polishing |

| 4-8 | W7 | 3000 | Li qub Polishing |

| 4-9 | W 10 | 2500 | Li qub Polishing |

| 5-10 | W 10 | 2000 | Li qub Polishing |

| 6-12 | W 10 | 1800 | Li qub Polishing |

| 8–12 | W 12 | 1600 | Li qub Polishing |

| 7–14 | W 14 | 1500 | Li qub Polishing |

| 8–16 | W 14 | 1300 | Li qub Polishing |

| 10-20 | W20- | 1200 | Li qub Polishing |

| 12-22 | W 20 | 1000 | Li qub Polishing |

| 15-25 | W 20+ | 800 | Li qub Polishing |

| 20-30 | W 28 | 700 | Li qub Polishing |

| 22-36 : kuv | W28+ | 600 | Rough sib tsoo |

| 20-40 | W40- | 500 | Rough sib tsoo |

| 30-40 | W 40 | 450 | Rough sib tsoo |

| 35-45 : kuv | W 40+ | 400 | Rough sib tsoo |

| 36-54 : kuv | W 50 | 350 | Rough sib tsoo |

| D46 | 325/400 ib | 320 | Rough sib tsoo |

| D54 | 270/325 ib | 270 | Rough sib tsoo |

| D64 | 230/270 ib | 230 | Rough sib tsoo |

| D76 | 200/230 | 200 | Rough sib tsoo |

4. Lwm yam Coarse Grit Loj

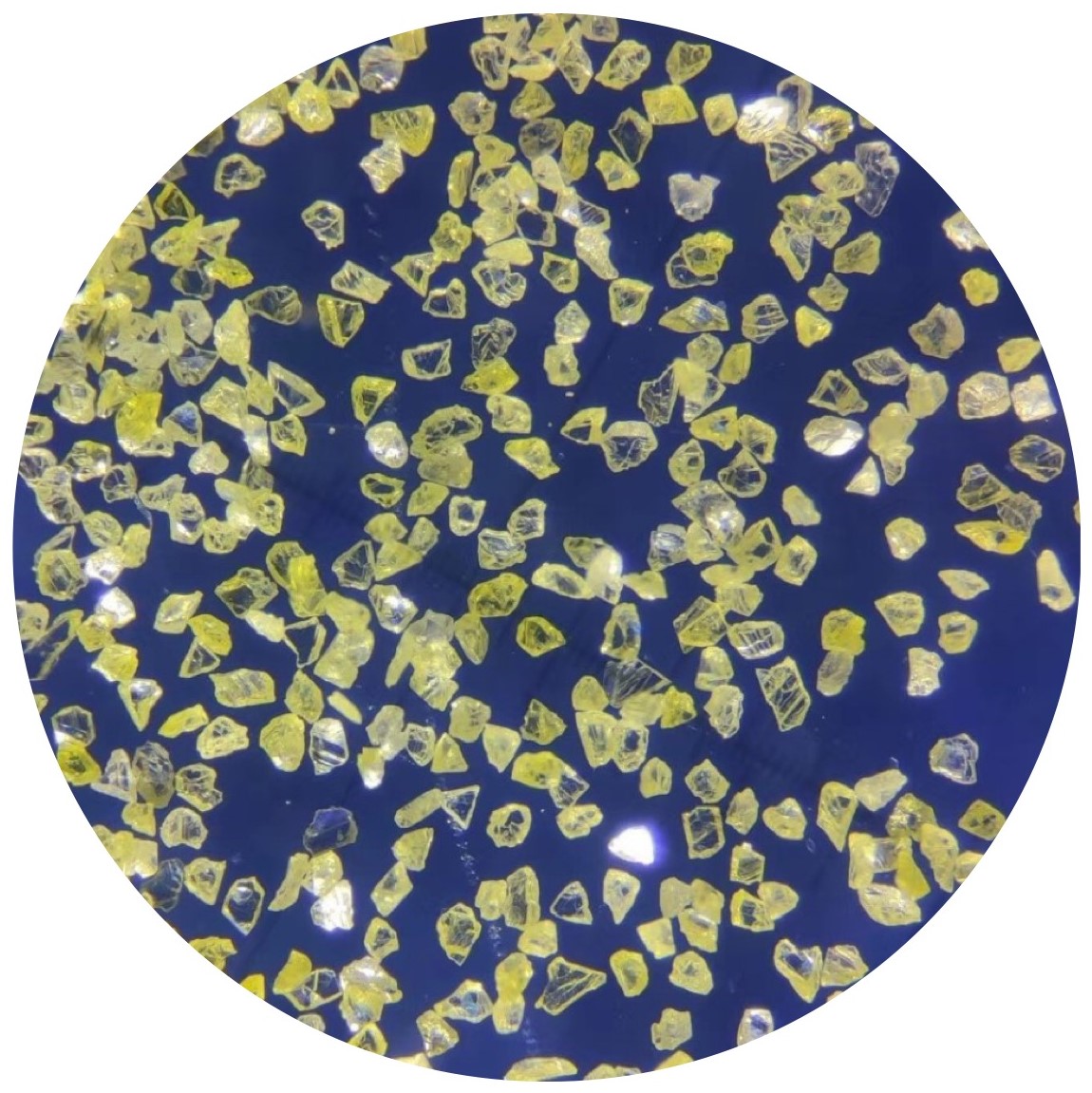

| 50/60-325/400 | Lub teeb ntsuab xim, irregular puab nrog qis toughness.Dav dav siv rau kev ua pob zeb, pob zeb, ceramics, thiab lwm yam. | |

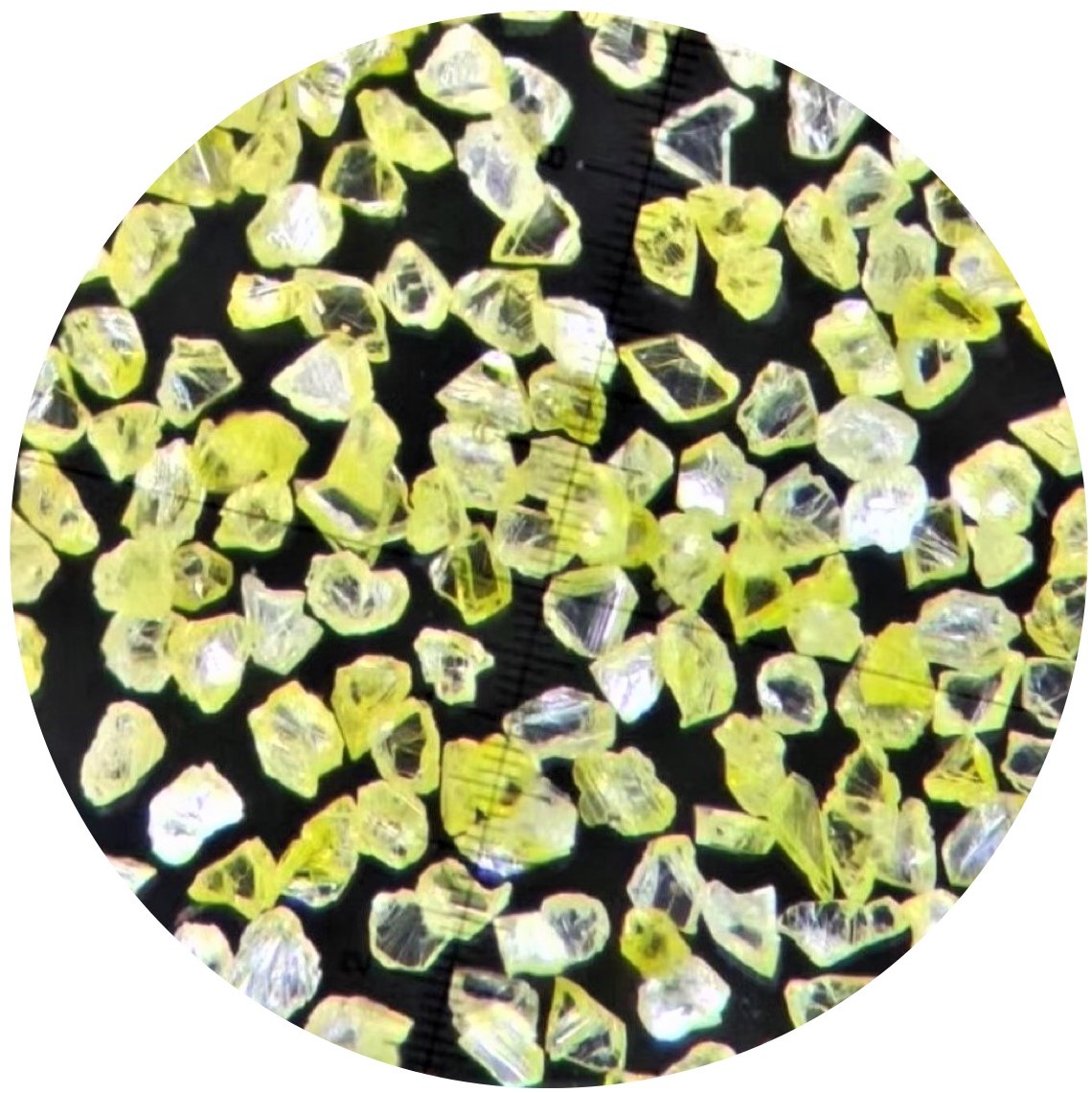

| 30/35-325/400 | Cov xim daj, cov duab tsis xwm yeem nrog tus qauv hardness, Siv rau hauv ceramic bonded, resin bonded thiab txhua yam ntawm electroplating cov khoom, rau cov pob zeb ua, tawv alloy, cov khoom sib nqus, ntuj pob zeb, pob zeb. | |

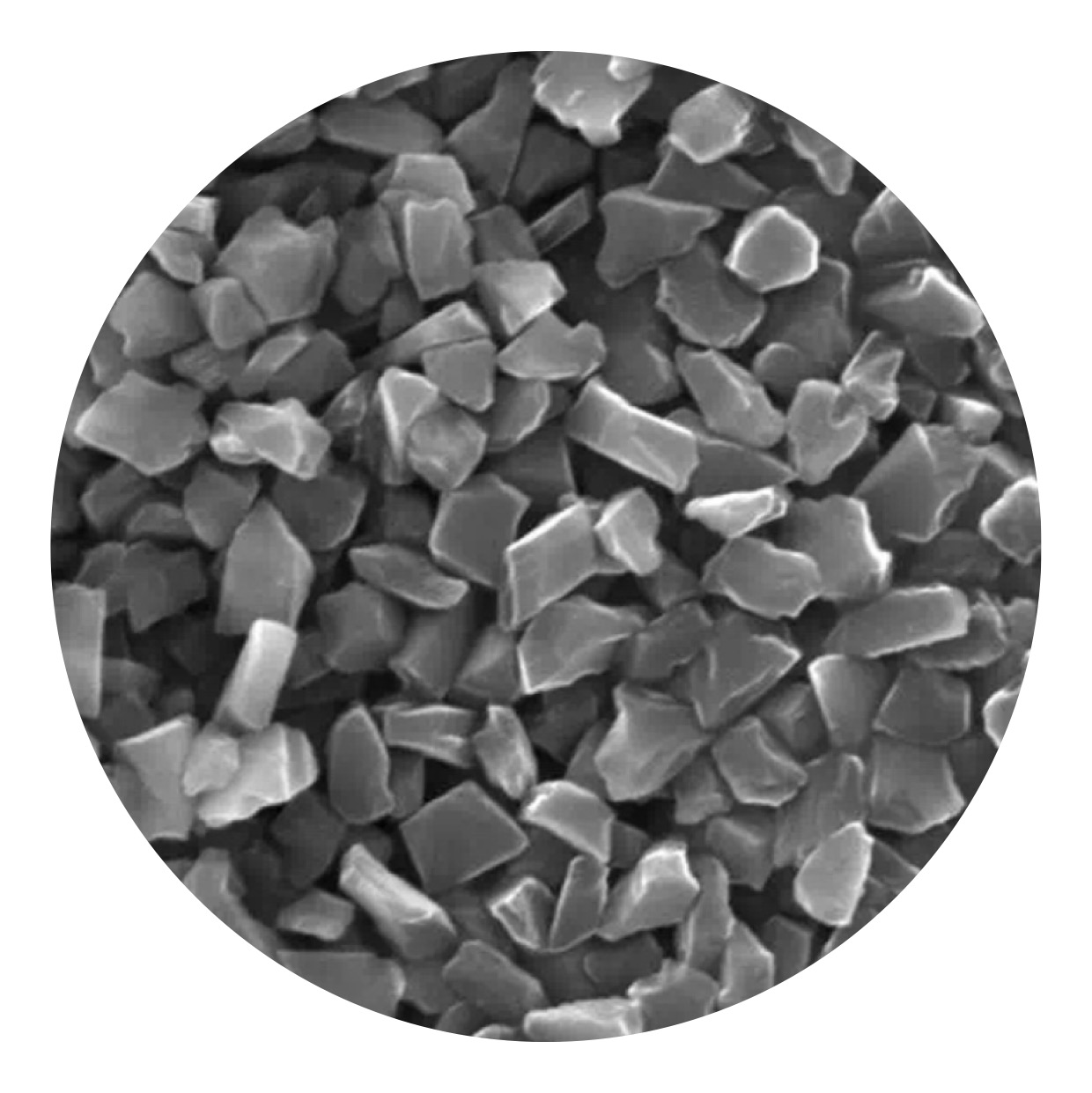

| 30/35-325/400 | Cov xim daj, siab hardness thiab toughness.Siv hauv ceramic daim ntawv cog lus, resin daim ntawv cog lus thiab txhua yam khoom siv electroplating, tuaj yeem ua tau siv rau kev ua haujlwm hnyav ntawm carbide, iav, ceramics, pob zeb thiab lwm yam khoom tsis yog xim hlau. |