SND-PL Polycrystalline Synthetic Micron Pob Zeb Diamond Hmoov Polishing Superabrasives

SND-PL Polycrystalline Synthetic Micron Pob Zeb Diamond Hmoov Polishing Superabrasives

1. Micron Pob Zeb Diamond Hmoov Taw Qhia

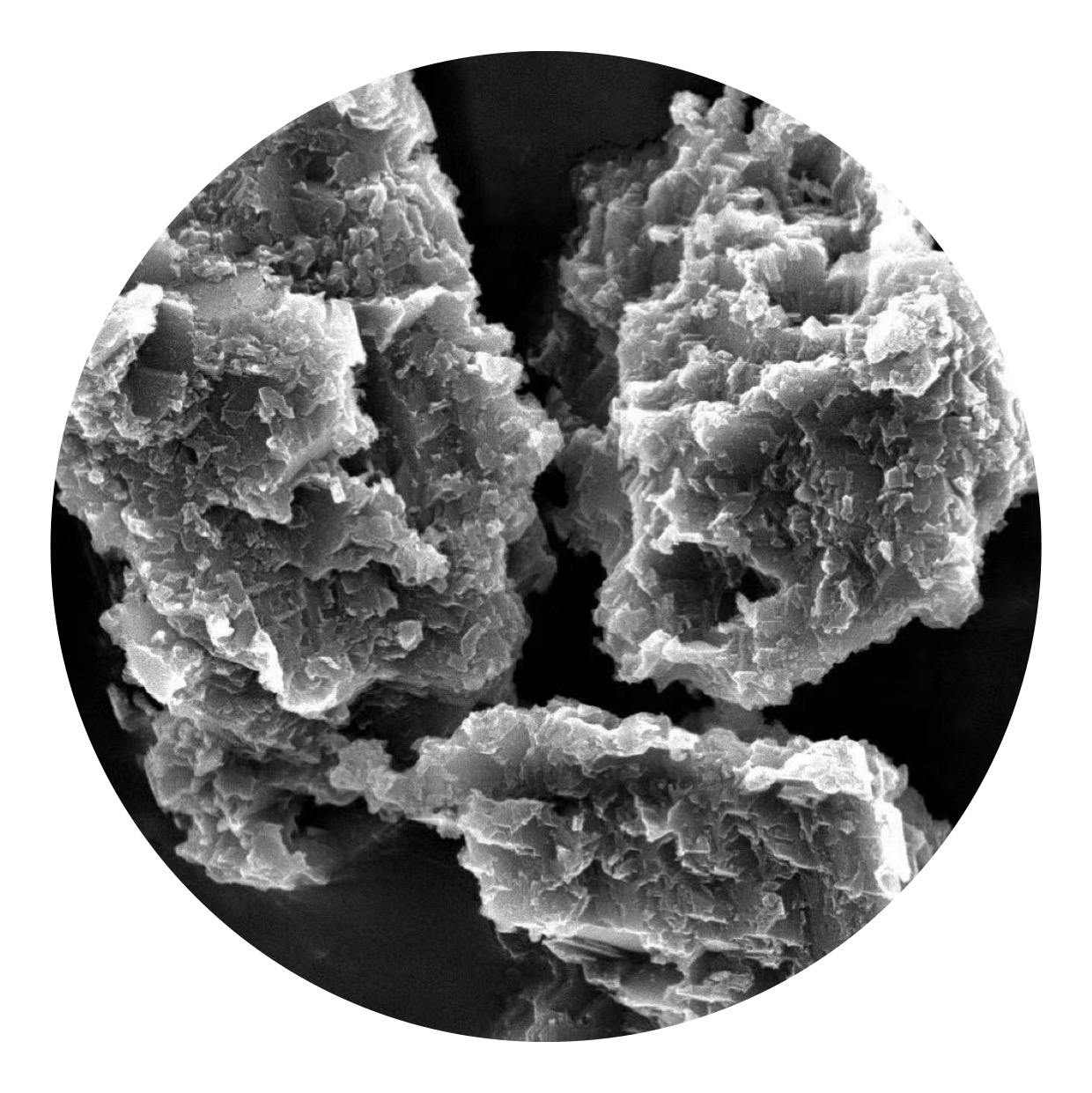

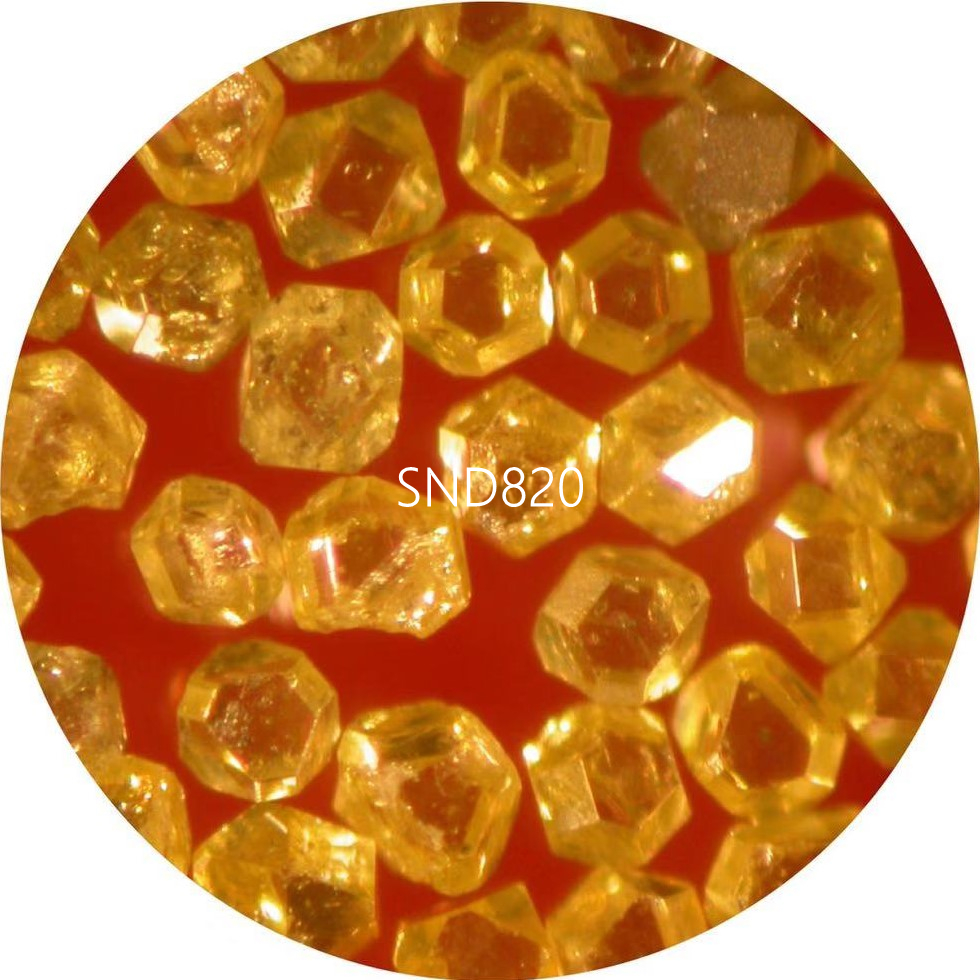

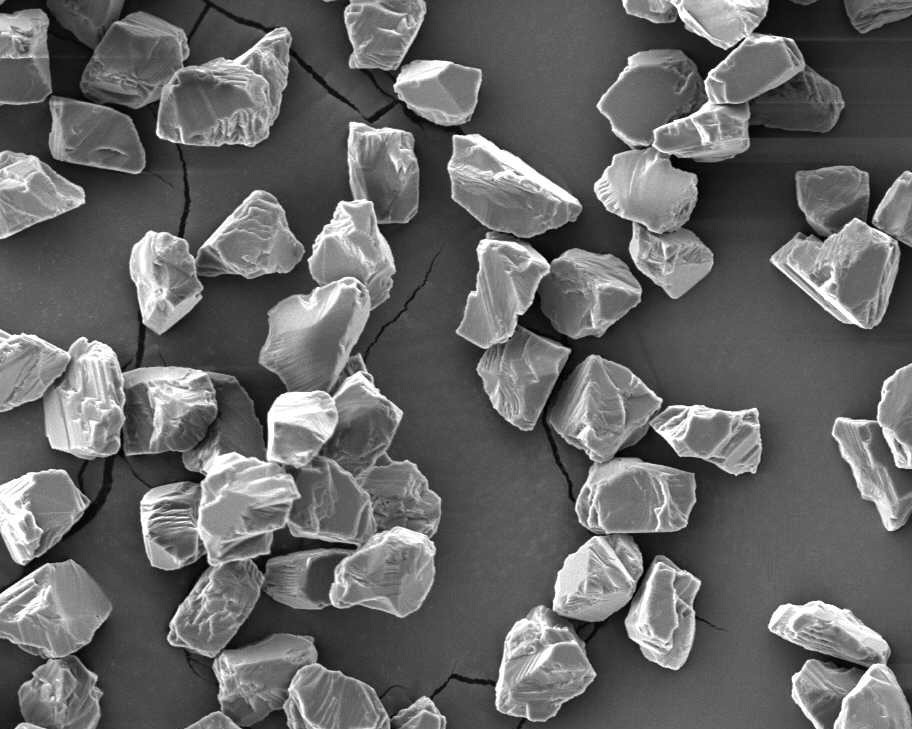

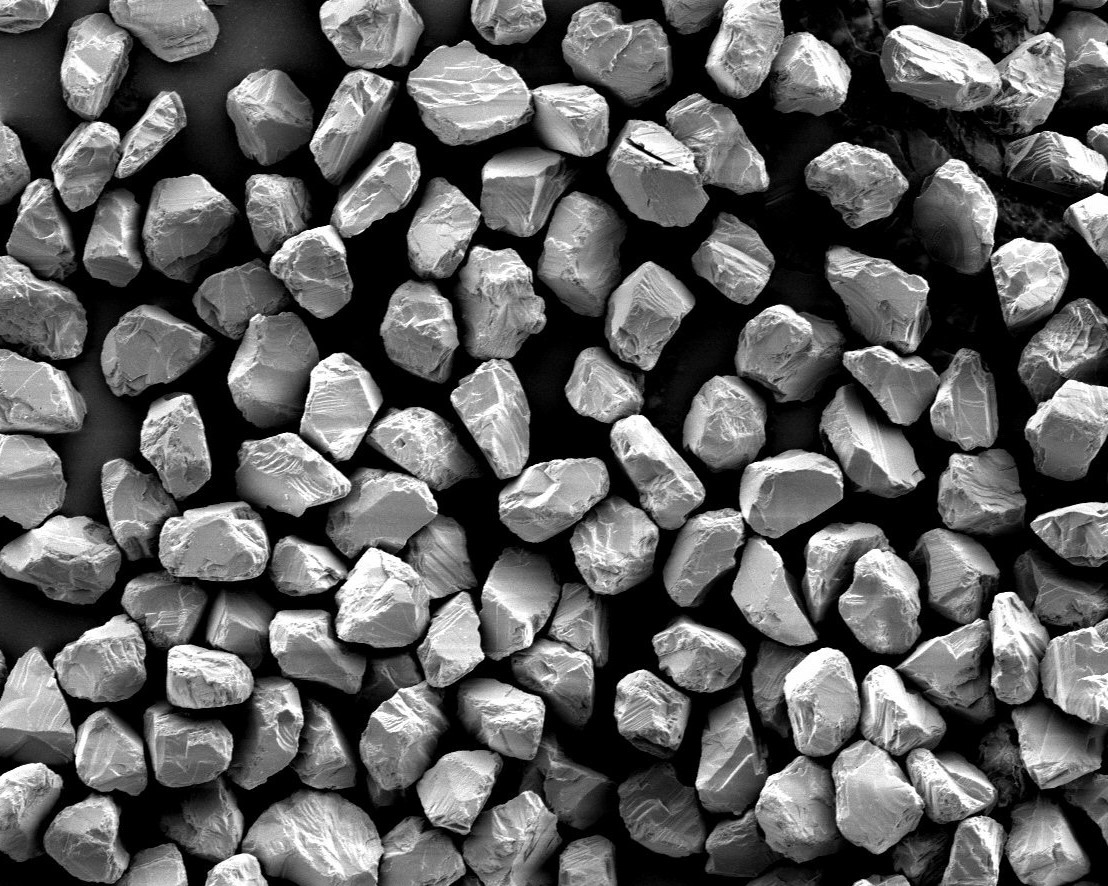

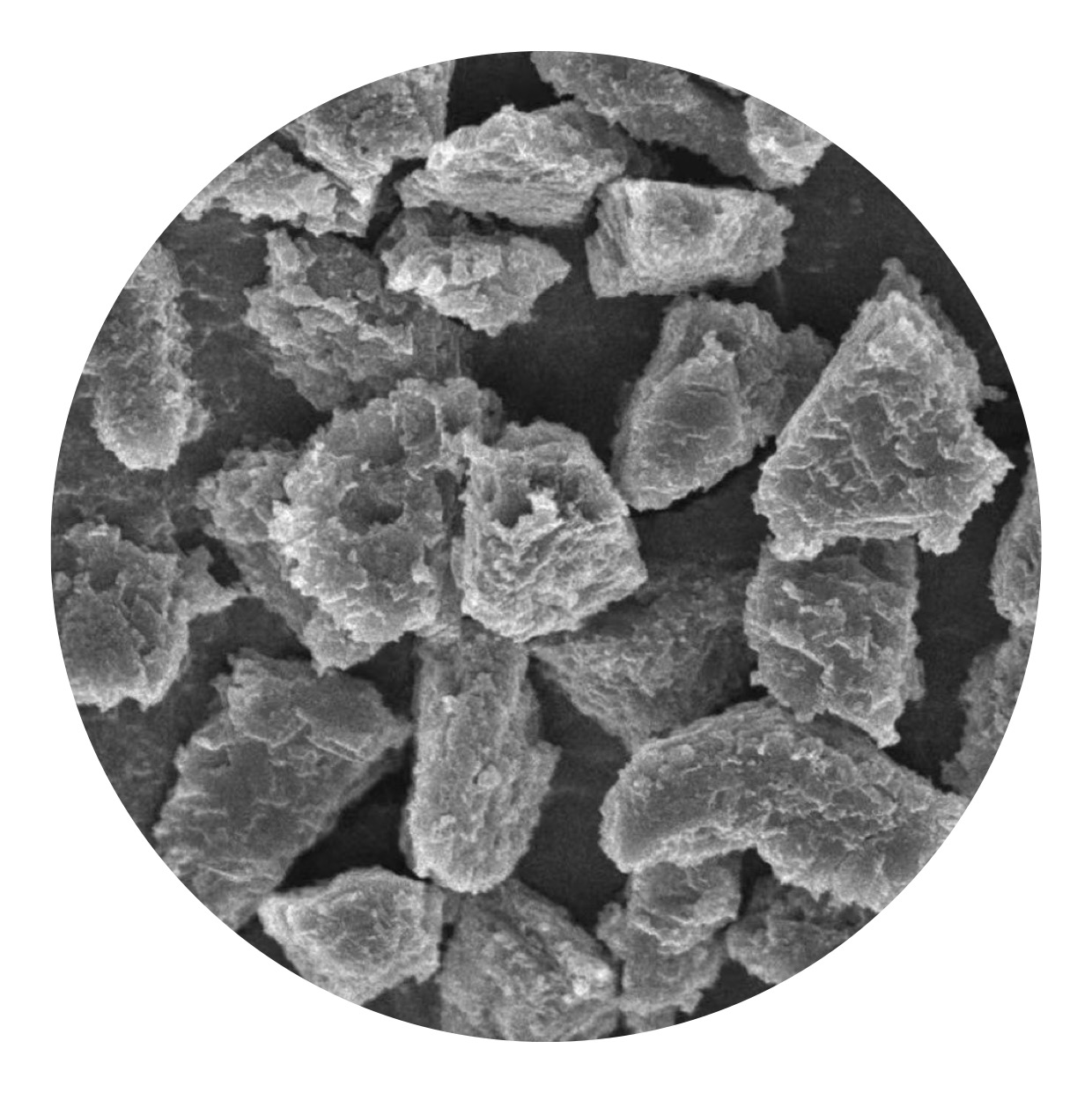

Poly-zoo li pob zeb diamond muaj qhov zoo sib xws li cov pob zeb diamond polycrystalline, tab sis tus nqi qis dua.Nws yog tsim los ntawm cov pob zeb diamond micron, nrog rau kev kho mob tshwj xeeb, cov pob zeb zoo li poly-zoo li pob zeb diamond muaj muti deavtivation npoo, cov npoo ntawm honeycomb tuaj yeem pab polishing nto ntawm khawb.

Sib piv nrog cov pob zeb diamond li niaj zaus, cov pob zeb zoo li poly-zoo li pob zeb diamond muaj qhov zoo ntawm kev ua haujlwm zoo dua, zoo dua polished roughness, thiab tsawg dua qhov seem deposits.

Lwm cov cim suav nrog:

- Efficiency: Lub muti nto npoo tuaj yeem txhim kho polishing thiab lapping efficiency 2-4 npaug siab dua li cov pob zeb diamond micron li niaj zaus.

- Precision: qhov tsawg toughness thiab passivation npoo tuaj yeem lav qhov polishing nto.

- Lub neej ntev: lub ntsej muag texture tuaj yeem pab cov neeg kho tshuab tuav nruj kom ua tiav lub neej ntev.

2. Specification ntawm Micron Pob Zeb Diamond Hmoov

|  |  |

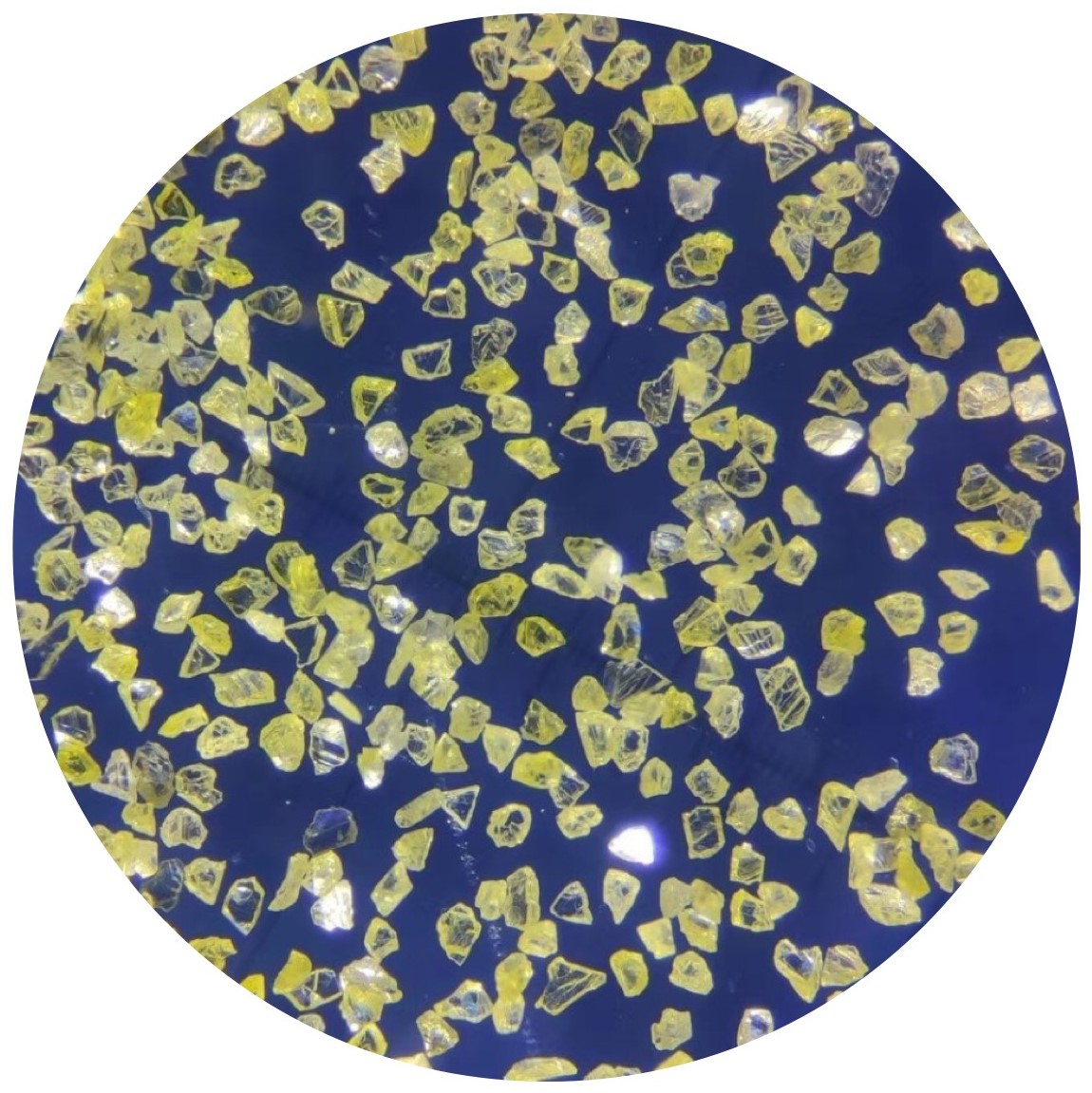

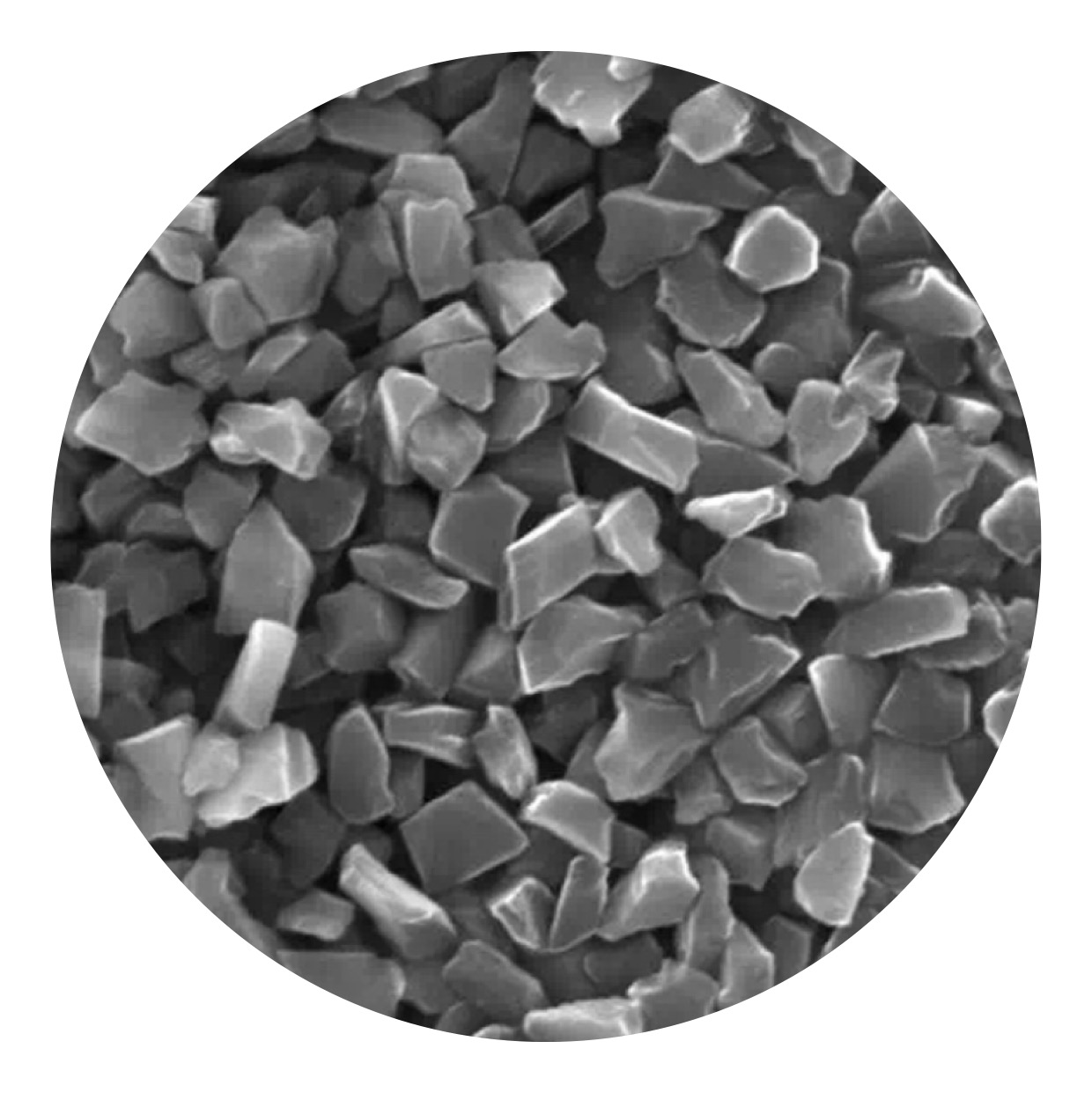

| SND-M/DW 0-0.125 ~ 40-60 | SND-M/PCD 0-0.125 ~ 40-60 | SND-M/PL 0-0.125 ~ 40-60 |

| Uniform particle loj thiab cov duab. Formaking silicon wafer txiav pob zeb diamond hlau, hniav nyiaj hniav kub saw, semiconductor saws. | Tshwj xeeb tsim rau PCD / PDC daim ntawv thov, siab lub zog blocky crystal puab, concentrated particle loj kev faib tawm, tsis tshua muaj impurity, Cov ntsiab lus qis Si, zoo thermal stability thiab hnav tsis kam. Kuj tseem siv tau rau siab zoo hlau daim ntawv cog lus, vitrified bond thiab electroplated cov khoom. | Poly-zoo li pob zeb diamond muaj lub zoo ib yam li cov polycrystalline pob zeb diamond, tab sis tus nqi qis dua.Nws yog ua los ntawm cov cais pob zeb diamond micron, nrog tshuaj kho mob tshwj xeeb, poly-zoo li pob zeb diamond muaj muti deavtivation ntug, cov honeycomb ntug tuaj yeem pab polishing nto tawm ntawm khawb. |

3. Micron Pob Zeb Diamond Muaj Grit Loj

| International Standard | Tuam Tshoj Standard | Mesh Loj | Daim ntawv thov |

| 0-0.1 hli | W 0.1 | 100000 | Super Daim iav Polishing |

| 0.0.25 Nws | wb 0.25 | 60000 | Super Daim iav Polishing |

| 0-0.5 hli | wb 0.5 | 30000 | Daim iav Polishing |

| 0-1 | W1 | 15000 | Daim iav Polishing |

| 0-2 | W1.5- | 13 000 | Zoo Polishing |

| 1-2 | W 1.5 | 12000 | Zoo Polishing |

| 1-3 | W 2.5 | 10000 | Zoo Polishing |

| 2-4 | W 3.5 | 6500 ib | Zoo Polishing |

| 2-5 | W4 | 5000 | Zoo Polishing |

| 3-6 | W5 | 4000 | Zoo Polishing |

| 4-6 | W6 | 3500 | Zoo Polishing |

| 4-8 | W7 | 3000 | Li qub Polishing |

| 4-9 | W 10 | 2500 | Li qub Polishing |

| 5-10 | W 10 | 2000 | Li qub Polishing |

| 6-12 | W 10 | 1800 | Li qub Polishing |

| 8–12 | W 12 | 1600 | Li qub Polishing |

| 7–14 | W 14 | 1500 | Li qub Polishing |

| 8–16 | W 14 | 1300 | Li qub Polishing |

| 10-20 | W20- | 1200 | Li qub Polishing |

| 12-22 | W 20 | 1000 | Li qub Polishing |

| 15-25 | W 20+ | 800 | Li qub Polishing |

| 20-30 | W 28 | 700 | Li qub Polishing |

| 22-36 : kuv | W28+ | 600 | Rough sib tsoo |

| 20-40 | W40- | 500 | Rough sib tsoo |

| 30-40 | W 40 | 450 | Rough sib tsoo |

| 35-45 : kuv | W 40+ | 400 | Rough sib tsoo |

| 36-54 : kuv | W 50 | 350 | Rough sib tsoo |

| D46 | 325/400 ib | 320 | Rough sib tsoo |

| D54 | 270/325 ib | 270 | Rough sib tsoo |

| D64 | 230/270 ib | 230 | Rough sib tsoo |

| D76 | 200/230 | 200 | Rough sib tsoo |